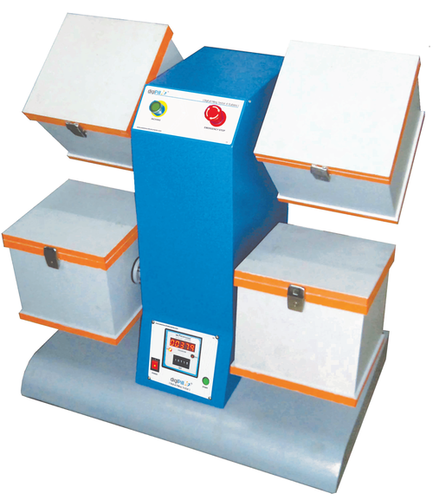

DetectMASTER i9 (100 mm)

Product Details:

DetectMASTER i9 (100 mm) Price And Quantity

- 100 INR/Unit

- 1 Unit

DetectMASTER i9 (100 mm) Trade Information

- Delhi

- 3-4 Week

- Contact us for information regarding our sample policy

- South America Western Europe Middle East Africa Central America Asia Eastern Europe North America Australia

- All India

- ISO Certified

Product Description

The minute pieces of broken needles in the baby garment can be dangerous to the health as the babies cannot tell if they are hurt with broken particle. So in order to avoid any mis happening, certain countries (for e.g. Sweden, Japan etc) have made it mandatory that whatever any under garment or baby garments enter their country, needs to be passed through the needle detector machines.

Paramount DetectMASTER i9 (100 mm) is a specialized equipment, with advanced electronic circuitry having latest control panel, which eliminates all chances of the broken needle parts to escape. It can detect any iron particle as small as 1.0 mm. Instead of the conventional 8 magnetic sensors, it is a 10-sensor unit which ensures its accuracy and dependability. The lightening indicator on the digital control panel makes it convenient for the operator to find the location of the broken needle. Further the digital counter on the panel can also calculate how many units have successfully passed the test and how many have failed. It also gives the total number of items tested on the unit. The Equipment works on the magnetic induction principal .The equipment has a detecting width of 600 mm with an effective detecting height of 100 mm.

SALIENT FEATURES

Specially designed instrument to detect broken needle or any ferrous particles in a garment

Latest model with modern aesthetics

Works on the magnetic induction principal

The smallest ferrous particle it can detect is 1.0 mm

Product width up to 600mm can be easily checked in this machine

Garments up to 100mm thickness can be easily checked

An alarm sounds at the detection of any broken needle & the belt stops and comes back to its original position

Specially designed Caster wheels at base for easy movement of the machine

Complete with all accessories along with 1 mm card to check calibration

Supplied complete with Calibration Certificate (Traceable to NPL)