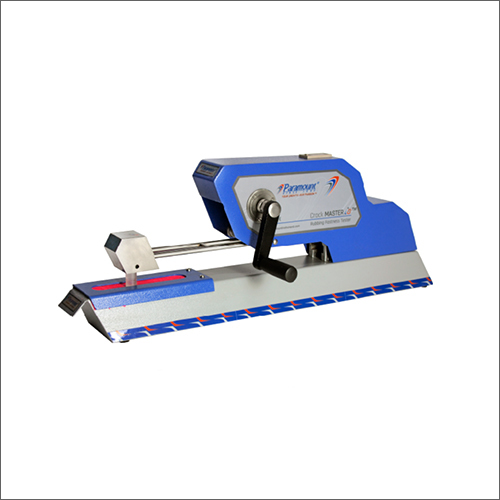

AutoBoard i9 (Motorized)

Product Details:

- Dimension (L*W*H) 36x15.5x14 Inch (in)

- Weight 32 Kilograms (kg)

- Click to View more

AutoBoard i9 (Motorized) Price And Quantity

- 10 Unit

- 100 INR/Unit

AutoBoard i9 (Motorized) Product Specifications

- 32 Kilograms (kg)

- 36x15.5x14 Inch (in)

AutoBoard i9 (Motorized) Trade Information

- Delhi

- 3-4 Week

- Contact us for information regarding our sample policy

- Australia North America South America Eastern Europe Western Europe Middle East Africa Central America Asia

- All India

- ISO Certified

Product Description

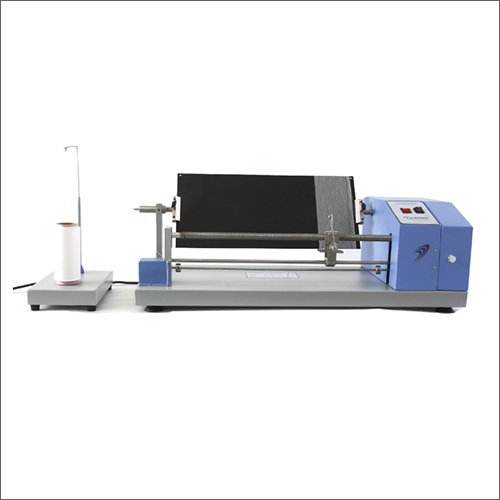

Visual determination of unevenness along the length of a yarn is carried out by wrapping it in equally spaced parallel wraps over a board and comparing the appearance of irregularities against STANDARD RATING PHOTOGRAPHS. As the yarns of different thickness are to be assessed, the spacing between the wraps is suitably selected so as to give a clearly distinguishable Pattern.

PARAMOUNT Auto BOARD i9 (Motorized ) is advanced model to wrap all types of yarns on tapered/parallel board (black). Th e lead screw is provided parallel to the axis o f the boards which gives the motion to the yarn for equal spacing and a tensioner device i s provided to give tension to the yarn.

The equipment has six step pulleys, so that the winding pitches can be varied to suit the count of yarn to be wrapped. It has an electrically control drive which stop automatically when the yarn reaches at the end of the board. The equipment gives the result as per ASTM Standard D2255. The equipment is mounted on a rigid base finished with Metallic Blue P.U paint. The other parts are made of S.S for long life trouble free operations.

SALIENT FEATURES

To determine the Evenness, Hairiness, Naps & Other Imperfection in a sample of Yarn.

Specially Designed Motorized Model.

Bobbin Holding Stand, which can accommodate All Size Bobbins.

Electrically Control Drive Which Stops Automatically.

As per ASTM Standard D2255.

Dual Yarn Wrapping Boards Tapered/Parallel Board.

Complete with all Accessories including, Bobbin Stand, Tapered/Parallel Boards

User s Manual with Inspection and Calibration Certificates.

Supplied complete with Calibration Certificate (Traceable to NPL)