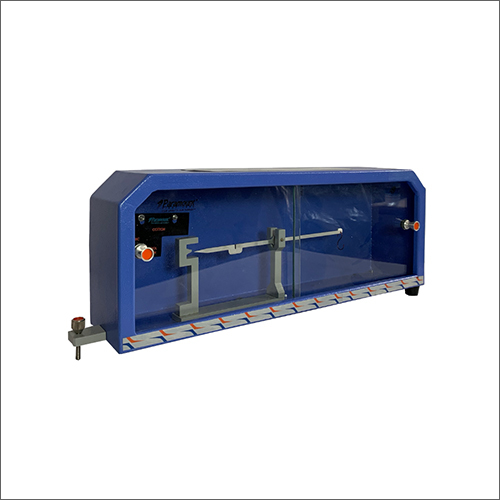

Motorised Multi Yarn Twist Tester

100 INR/Unit

Product Details:

- Dimension (L*W*H) 1120x480x370 Inch (in)

- Weight 14 Kilograms (kg)

- Click to View more

X

Motorised Multi Yarn Twist Tester Price And Quantity

- 10 Unit

- 100 INR/Unit

Motorised Multi Yarn Twist Tester Product Specifications

- 1120x480x370 Inch (in)

- 14 Kilograms (kg)

Motorised Multi Yarn Twist Tester Trade Information

- Delhi

- Paypal Letter of Credit (L/C) Cash on Delivery (COD) Western Union Letter of Credit at Sight (Sight L/C) Cash Against Delivery (CAD) Telegraphic Transfer (T/T) Delivery Point (DP) Days after Acceptance (DA) Cash in Advance (CID) Cheque Cash Advance (CA)

- 3-4 Week

- Contact us for information regarding our sample policy

- Australia North America South America Eastern Europe Western Europe Middle East Africa Central America Asia

- All India

- ISO Certified

Product Description

A Motorised Twist Tester is used to find out the accurate twist of all yarns except gummed silk yarn. It is operating under the principle of single untwist twist method (twist contraction) for testing single yarns. Untwist only method for testing plied (and double) yarns. Triple untwist twist method for opened yarns.

Paramount Twist Tester i9 (Motorised, Multi Yarn) is a Next Generation software driven Equipment. It consists of a fixed base on which the main scale is provided to set the length of the specimen yarn. A panel board is mounted on the right-hand side of the base to control and perform all operations of the instrument. On the left-hand side of the base, the tensioning device is provided to hold the yarn. This tensioning device is mounted on a moving carriage having stationery yarn gripper Jaw, elongation scale, tension (elongation relief) stoppers and a tension weight pan. The moving carriage can be adjusted up to 20 inches/50cms to set the length of the specimen yarn. A Carriage knob is provided on the moving carriage to lock it at any required gauge length. The rotating jaw (gripper) is mounted on left hand side of the control unit which is directly coupled with a high procession DC motor. A spring-loaded jaw is provided in the rotating jaw to hold the specimen yarn. A knurled rotary knob is fixed with the rotating jaw for manual rotation. A Fine speed controller is provided to adjust the speed of rotating jaw. A separate yarn bobbin stand is supplied to rest and draw the specimen yarn while testing.

| Country of Origin | Made in India |

| Brand | Paramount |

| Color | Blue & Grey |

| Automation Grade | Automatic |

| Voltage | 220v/50hz |

| Power | 220v |

SALIENT FEATURES

- Latest microprocessor-based Next Gen. equipment used to determine the twist per inch/cm

- Specially designed for single yarn, double yarn & open-end yarns

- A special sensor for zero setting

- Special adjustable tensioning device provided to give tension to the yarn while testing

- Totally programmable unit

- User-friendly control panel, which guides the operator to undertake all steps for testing

- Smooth precision-engineered auto mechanism

- 1 to 50gm Tension weight supplied to give proper tension during testing

- Digital control panel with 40-character, 2-line LCD display

- Knurled rotating jaw for easy manual rotation

- A specially designed yarn bobbin stand is supplied to rest and draw the specimen yarn while testing

- Supplied complete with Calibration Certificate (Traceable to NPL)

Other Products in 'Yarn Testing Machine' category

"We are accepting bulk order quantity only."